SRM Inspection is a small company, whose aim is to provide a reliable personal customer service with a commitment to maintaining high standards of NDT inspection throughout the North West of England. Our 25 years of experience has been mainly in … Read More about About Us

Main Content

-

Ultrasonic Inspection

The Ultrasonic inspection process utilises the use of a pulse echo type flaw detector which operates at 1-5 Mhz. This is used to detect and evaluate sub surface indications in welds and wrought … Continue Reading…

-

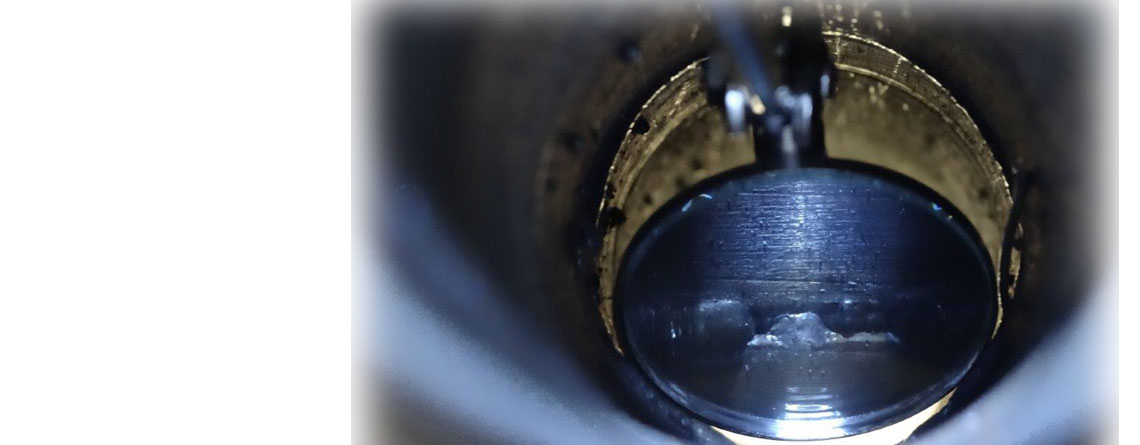

Visual Inspection

Visual inspection is carried out on 100% of the component under examination, prior to any form of NDT. Welding/visual inspection requires the use of the following:- Torches/lighting capable of … Continue Reading…

-

Magnetic Particle Inspection

The MPI process is used for detecting surface and near surface indications in ferromagnetic materials. The process uses inks: paints and electro and permanent magnets. The method involves the … Continue Reading…

Non Destructive Testing

Ultrasonics - PCN level II qualified in the Ultrasonic examination of welds and forgings Ultrasonic inspection is a method of NDT which is used for detecting flaws sub surface in any material type which is welded, cast or forged. Magnetic Particle … Read More about Non Destructive Testing

Service

Many companies who haven’t previously used NDT as a method of maintaining quality are now starting to do so. With the introduction of CE Marking Laws, companies are now aware that they often have contractual obligations to have a percentage of their … Read More about Service

SRM Inspection, with bases in Blackburn and Rochdale, Lancashire, serving customers from Merseyside, Greater Manchester, Yorkshire, Cheshire and Cumbria, is a Non Destructive Testing company with over 25 years experience and expertise in NDT and welding inspection.

We specialise in: Ultrasonics, Magnetic Particle Inspection, & Visual Welding Inspection.

We can also offer: NDT Level 3 Services, Welding Engineering Consultancy, Welder Qualifications, Welding Procedures, Dye Penetrant Testing and Radiography.

SRM inspection has experience in structural steel, offshore oil & gas, nuclear, transport and renewable energy.

Our aim is to give customers a highly skilled and flexible service. Whether it be in fabrication facilities or sites, we can meet your requirements from small one “off jobs” to large on ongoing contracts. We are a trustworthy, reliable, professional company which offers value for money and a wealth of expertise in this field.